Greaseweazle is an open source project intended to be a universal floppy disk archiving tool. It consists of a USB connected floppy drive controller with custom firmware and accompanying host tools.

Greaseweazle is an open source project intended to be a universal floppy disk archiving tool. It consists of a USB connected floppy drive controller with custom firmware and accompanying host tools.

“By extracting the raw [magnetic] flux transitions from a drive, any disk format can be captured and analysed: PC, Amiga, Amstrad, PDP-11, musical instruments, industrial equipment, and more.”

The Controller Board

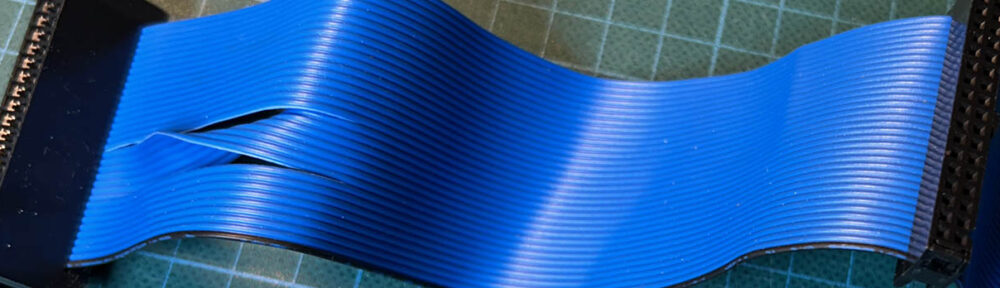

Several hardware models are available. The simplest one – called F1 – requires no more than an inexpensive STM32F103 “Blue Pill” development board, a USB cable to connect to the host, and a ribbon cable to connect to the floppy drive. A small adapter board makes the wiring even easier.

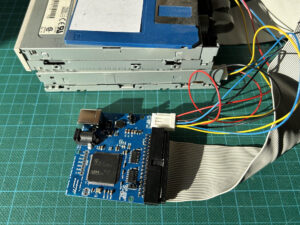

I’ve had the adapter PCBs and Blue Pill boards lying around for years, but I never got around to assembling one. Maybe partly because I actually wanted to build one of the more advanced models. So when I recently got the chance to buy an almost complete kit to build the “F7 Lightning Plus” model, I didn’t think twice.

The Disk Drives

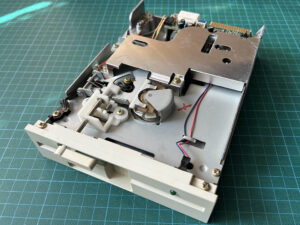

This model can actually control and power two different floppy drives and I really wanted to connect both a 5.25″ and a 3.5″ drive. The 5.25″ drives are surprisingly expensive these days, but I still had the drive from my first IBM compatible PC which would make a great match – or so I thought. Unfortunately though, it looks like the drive’s controller board didn’t survive the decades of disuse. When powered up, the stepper motor that drives the head starts spinning immediately without stopping.

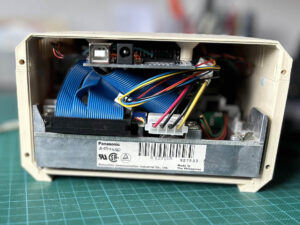

In a mild case of sunk cost fallacy, I then turned to eBay and payed too much money for a Panasonic JU-475-4 drive. At least, this drive was in working order when it arrived. And its jumpers should even allow me to read both sides of so-called “flippy disks” like those for the Commodore 1541.

The Build

Once I was satisfied that everything was working as intended, the only thing left to do was to design, construct, print, and assemble a nice case for my Greaseweazle Station. Unfortunately, the F7 board is not well suited for integration into such a case. So I did some modding first in order to get the LEDs and switches to the front.

But in the end, I’m quite happy with the result of this project. As soon as I get around to it, I will make the 3D files needed to print the case available in the usual places.